Some people say oil additives are a waste of money.

Others swear one saved their engine from total failure.

So which is it?

Are they real protection—or just expensive oil flavor?

A few popular YouTube tests made thousands of people give up on additives altogether. But here’s the thing: those tests often measure extreme scenarios—like running an engine dry—that don’t reflect how most engines actually live. Real engines deal with heat cycles, cold starts, slow wear, and thinning oil over time.

So maybe we’ve been judging additives by the wrong rules.

I Evan and I’m not here to sell you anything. I’m not here to say “everything works” or “it’s all snake oil.” I’m just looking at what actually happens—using history, chemistry, real-world driving, and bench tests—but with eyes wide open about what those tests can and can’t tell us.

The real question isn’t “which additive wins in a machine?” It’s “which one actually helps your engine over time?” and Which one is the Best Oil Additive?

In this Post, we’ll start with a proven classic: Liqui Moly MoS₂—the stuff militaries and mechanics trusted for decades. We’ll look at where it came from, why it worked, and where it still makes sense today. Then we’ll bring in Project Farm’s data, real user reports, and talk honestly about what those tests really show—and what they miss.

After that, we’ll compare it fairly to modern options like CeraTec, using the same logic every step of the way.

My goal isn’t to give you a ranking to copy. It’s to help you understand why something works—or doesn’t—so you can decide what’s right for your engine.

Let’s start with one of the oldest names in the game…

Oh! If you don’t love the idea to read the long article then no worry i have a Video. So You can instead watch my video in YouTube.

Liqui Moly MoS₂—and what it really does.

Liqui Moly isn’t just another oil additive brand you see online. It’s been around since 1957, and its MoS₂ formula has roots in real engineering history—used in aircraft and military engines long before social media existed.

MoS₂ is one of the oldest and most respected friction-fighters out there. Not because of hype, but because it actually sticks to metal when oil can’t.

Today, I’m not here to sell it or trash it. I just want to see: do the claims hold up—or fall apart—under real evidence?

Liqui Moly started in 1957 in Ulm, Germany—but the stuff inside it, MoS₂, goes way back.

It was first used in piston-driven aircraft engines, where losing oil pressure meant total engine failure. The U.S. military even used it during World War I and after.

That tells me something important: MoS₂ wasn’t made to “boost your MPG” or make your engine purr. It was built for survival-level lubrication—to keep metal from welding together when oil fails.

So yeah, it’s got real roots. But that doesn’t automatically mean it works the way people say it does today.

How Molybdenum Disulfide Actually Works (Real Science)

MoS₂ isn’t like regular oil—it’s a solid lubricant. Think of it as tiny slippery plates that stick to metal surfaces, especially where friction is highest and metal touches metal.

It forms a low-friction sacrificial film—meaning it takes the wear so your engine parts don’t have to.

This really matters during cold starts, when oil hasn’t pumped up yet, or in those rare moments when oil pressure drops.

I’ve looked into it, and this isn’t marketing fluff. It’s real tribology—the actual science of how things slide and wear.

What MoS₂ Does Well — and What It Was Never Meant to Do?

MoS₂ bonds to metal and can reduce wear when things get rough—like during a cold start or if oil pressure drops for a few seconds.

But it won’t fix a broken engine, and it’s not a substitute for good motor oil.

From what I’ve seen, its real value was always as insurance—a backup plan, not a miracle cure.

Liqui Moly’s Claims vs Fan Expectations?

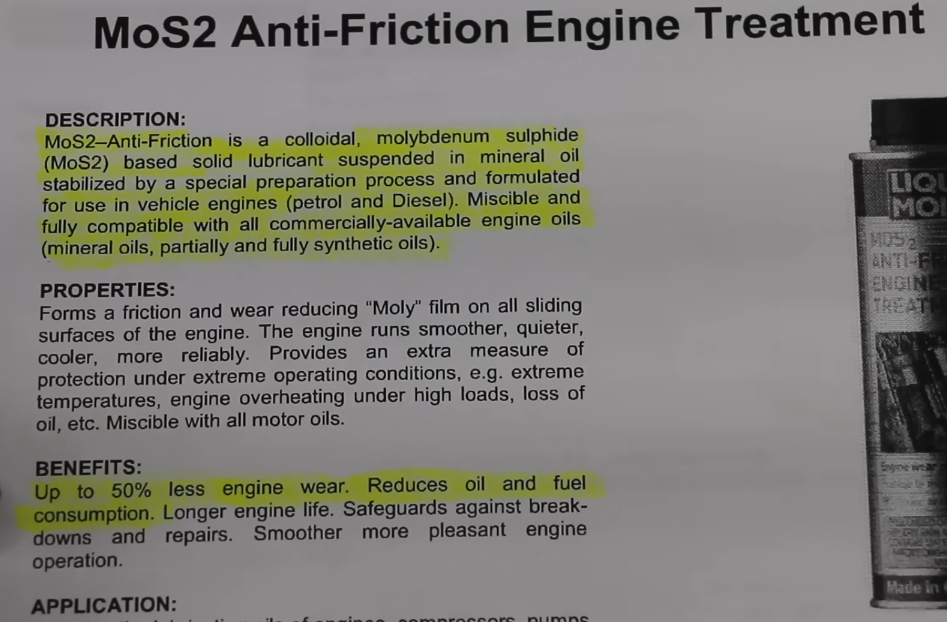

Liqui Moly says their MoS₂ cuts wear by up to 50%, protects during cold starts, and works in any engine. It’s all pretty general—vague engineering language, nothing too specific.

But fans? They’ll tell you their old car sounds quieter, starts easier in winter, or even feels “rejuvenated.” Some swear by it after decades of use.

The difference is clear: the company talks about what it might do; users talk about how it made them feel. And sometimes, that feeling gets stretched into near-miracle territory—even if the science doesn’t quite back it up.

Key Question Before Testing

So here’s the big question: Do these claims actually show up under controlled, measurable conditions?

That’s why I’m using Project Farm’s test as a starting point. They’ve become a consistent benchmark for stuff like this—not perfect, but fair, repeatable, and honest.

For this whole series, their method is our testing standard. Not because they’re the final word—but because it gives us a common ground to compare everything else.

Project Farm Test (What Was Actually Tested)

Project Farm tested Liqui Moly MoS₂ in three practical ways—no fancy lab gear, just real-world setups you could replicate.

First, he ran a small gasoline engine with the throttle locked in place. The idea: if friction really drops, the engine should spin faster with the same fuel and air. He tried it with regular 10W-30 oil, then again after adding the recommended dose of MoS₂.

Result?

No change in RPM.

Second, he used a mechanical lubricity tester—a spinning wheel pressing on a bearing under load. One test used plain oil, the other used oil with MoS₂ added. After 30 seconds, he checked both bearings. Visually, the wear looked the same. No clear advantage.

Third, he hooked the engine to a generator and put a steady 1500-watt load on it—like running a microwave and a few lights. He filled the fuel tank to the brim each time. With plain oil, it ran for 58 minutes. With MoS₂ added? Again, 58 minutes. No gain in runtime, which means no improvement in fuel efficiency.

So the short-term takeaway is simple: under these conditions, there were no measurable benefits—not in friction, not in fuel use. That doesn’t mean it never works, but it does challenge claims about quick or obvious results.

Addressing the Backlash Around the Test

After Project Farm’s video dropped, a lot of people online started saying MoS₂ is useless—some even called it a total scam. The test became this flashpoint: “See? It doesn’t work!”

But not everyone agreed. A few viewers pushed back, pointing out possible flaws in how the test was run. And honestly, some of those objections do have merit—while others miss the mark.

I’m not here to blindly defend Project Farm, and I’m not here to dismiss MoS₂ just because one test came up empty.

So let’s sort through the noise. I’ll go over the most common criticisms—especially from people who actually use and trust the product—and check which ones hold up under closer inspection. Because when something’s been around this long, it deserves more than a hot take.

#1 He Tested Raw MoS₂

Some viewers said Project Farm tested “raw MoS₂” by itself—like pure powder—not mixed with oil.

But that’s not what happened. Liqui Moly MoS₂ is a liquid additive, already suspended in oil. He added it to 10W-30 exactly as the bottle says.

So this criticism? It’s based on a misunderstanding of what the product actually is.

#2 Lawnmower ≠ Car Engine

Some folks argue a lawnmower engine isn’t the same as a modern car engine—and they’re partly right. Today’s engines are more complex, and one test ran with no real load.

But Liqui Moly sells MoS₂ as universal—for cars, mowers, motorcycles, you name it. If it only works in high-tech turbo engines, they should say so.

And if an additive shows no effect in a simple system, it’s fair to be skeptical—because real benefits usually show up somewhere, even in basic setups.

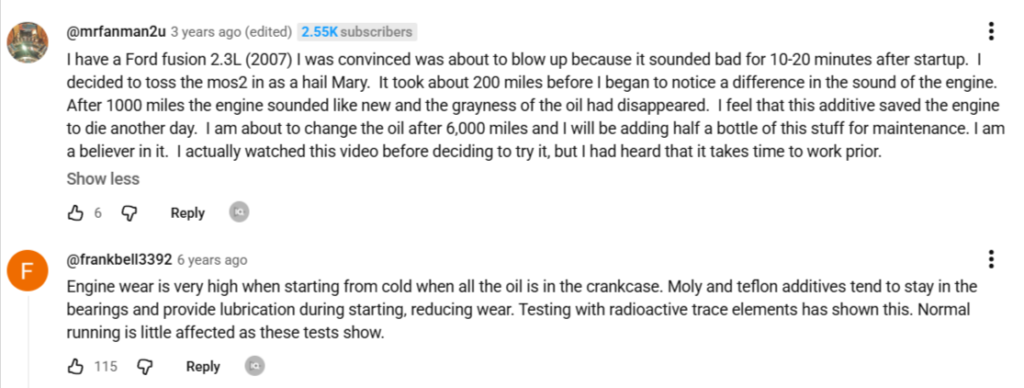

#3 The Most Important Criticism: MoS₂ Needs Time, Heat & Load

This one’s fair: MoS₂ isn’t instant. It needs time, heat, and real pressure to form that slippery layer on metal—what experts call a tribofilm.

Many users say it takes about 500 miles of driving before you notice anything. Project Farm’s tests only ran for an hour or so—nowhere near enough time for that process to really kick in.

So yes—I agree. His test probably didn’t give MoS₂ enough time or mechanical conditioning to fully activate. That matters.

Why the Test Is Still Valuable

The bottle doesn’t say “wait 500 miles” or “effects delayed.” Most people add it expecting quick results—smoother idle, better mileage, right away.

So while the test doesn’t rule out long-term benefits, it clearly shows: instant gains? Probably not real.

Liqui Moly MoS₂ is built on real science and has a solid history—especially in situations where oil fails or can’t reach metal fast enough. I think of it less as a performance booster and more as insurance.

It makes the most sense for cold starts, older or worn engines, or those rare moments when oil pressure drops. In those cases, that thin moly layer might really help reduce wear.

But don’t expect better fuel economy. Any MPG change would be at the decimal level—if you see anything at all—and often it’s just your engine running smoother because it’s cleaner or you’re driving differently.

It’s not needed in a healthy, modern engine with good oil, and it won’t give you instant power gains.

Project Farm’s test didn’t back up the big performance claims—and that’s fair. But it also doesn’t cancel out MoS₂’s role as a backup during those critical seconds when oil isn’t there yet.

Why Industrial Use Confirms MoS₂ Works

So if you’re wondering whether MoS₂ actually works at all—look beyond cars. It’s widely used in wind turbine gearboxes, where reliability over decades matters. It’s in sealed industrial gears, and even in heavy-duty power tools like Hilti drills and angle grinders.

In those settings, it’s not added for show. It’s there because under high pressure, heat, and constant grinding action, MoS₂ forms a durable, low-friction layer that really does extend life.

The key? It needs time and load to work—exactly what those machines provide every day.

So yes, MoS₂ absolutely works. Just not instantly, and not in the way most car owners expect. It’s a slow, steady protector—not a quick fix. And that’s why its real value shows up in long-term, high-stress environments, not in a one-hour engine test.

Cold-Start Wear: Where MoS₂ Truly Shiness

If MoS₂ has a sweet spot, it’s right here: cold starts.

Studies show 60–80% of engine wear happens in the first few seconds after you turn the key—because oil drains to the pan when the engine’s off. That’s even why pre-oiler systems exist: to pump oil before startup.

MoS₂ sticks to metal even when oil isn’t there yet. It gives a thin, dry-film layer that reduces metal-to-metal contact during those critical seconds.

Honestly? This is MoS₂’s strongest case—and the one I feel most confident about.

Film-Strength Tests: Why People Misinterpret Them

Now, about those “film-strength” tests you see online—like the ones where metal balls get crushed together. My take? They’re only partially useful, and people often read too much into them.

They can show which additive handles extreme pressure better—but that’s not the same as proving it will protect your engine over time.

Project Farm used a common film-strength-style test: a spinning wheel pressing on a bearing under load, comparing plain oil to oil with MoS₂ added. The idea was to see if the additive reduced wear in high-friction conditions.

But here’s what that kind of test can’t tell you: whether an engine will last longer, run cleaner, or stay protected over thousands of miles. Film-strength tests were made for industrial greases and gear oils—not car engines running under normal conditions.

So while his method gives a rough comparison, it doesn’t prove MoS₂ helps—or hurts—your engine long-term. A bad result here doesn’t mean it’s useless; a good one wouldn’t mean it’s magic. It’s just one narrow slice of a much bigger picture.

Why Project Farm Is Still Honest & Useful

Even with the limits of his test, Project Farm stays honest. He doesn’t claim his setup equals a real car engine. He shows the raw data, explains his method, and even says: “Results may vary in real engines.”

The real problem isn’t his test—it’s how some viewers treat it like final proof. But he never said that. And that’s why his work is still useful: it’s clear, fair, and upfront about what it can—and can’t—show.

So here’s the bottom line I keep coming back to:

Film-strength tests show what happens under extreme pressure—but not how an additive will perform in your engine over time.

They’re a snapshot of one narrow condition, not a forecast for long-term protection. And that’s a difference worth remembering.

Why We’ll Still Use These Tests for Comparison

Even though these tests have limits, they’re still useful—as long as we use them the same way every time.

Same tester. Same method. Same conditions.

Because even a flawed test can give helpful clues when it’s applied consistently across different products. That’s how we’ll compare them—not as proof of engine life, but as a relative benchmark.

Now that we’ve looked closely at MoS₂, let’s do the same for another popular option: Liqui Moly CeraTec.

It’s from the same brand, but uses ceramic instead of molybdenum—and makes some big claims of its own.

I’ll give it the same honest look: same test logic, same scrutiny, no favors. Let’s see how it really stacks up.

Liqui Moly CeraTec

We just spent a lot of time on Liqui Moly MoS₂—the old-school additive with real history, especially for cold starts and older engines.

Now, let’s look at its younger sibling from the same brand: Liqui Moly CeraTec.

Where MoS₂ is decades old, CeraTec is newer, built around ceramic particles, and marketed for modern and turbocharged engines.

It costs more, sounds high-tech, and claims to last up to 30,000 miles. But here’s what I’m wondering: compared to the last one we talked about… does it actually perform better?

What Is Liqui Moly CeraTec?

Liqui Moly CeraTec isn’t another molybdenum additive—it’s something different. Instead of MoS₂, it uses ceramic microparticles (a type of modified silicon dioxide) that are supposed to bond to metal surfaces inside your engine.

On paper, it sounds great: reduces friction, lowers fuel use, and forms a protective layer that lasts up to 30,000 miles—even through oil changes.

So if MoS₂ is the old-school workhorse, CeraTec is Liqui Moly’s newer answer for today’s engines—especially turbocharged ones that run hotter and tighter.

It’s a preventive additive, meant to form a long-lasting coating on metal parts. The formula mixes boron-based ceramic microparticles with some molybdenum compounds, which is partly why it costs more than regular MoS₂.

Here’s what I noticed: MoS₂ has been around for over 70 years. CeraTec? It’s the new kid on the block. And just because it’s pricier doesn’t automatically mean it works better. On paper it sounds great—but let’s see what actually happens when you put it to the test.

Manufacturer Claims Breakdown

Now that we know what CeraTec is, let’s look at what Liqui Moly actually says it does: reduces friction and wear, prevents metal-to-metal contact, cuts fuel use, and—here’s the big one—lasts up to 30,000 miles, even through oil changes.

Compared to the last one we talked about, these claims sound a bit more modern, a bit more polished.

But here’s the real question: do any of these show up in actual testing?

Because on paper it sounds great—but I’m not looking for miracles. I’m looking for measurable, realistic improvements. That’s what matters.

Project Farm Tests

Since we’re talking claims, it’s fair to ask: how do we test them? That’s where Project Farm comes in—his videos are popular because he gives real numbers, not just opinions. People trust him for that.

But here’s what I always keep in mind: his tests are bench-style. They don’t run a full car engine with piston rings, turbos, or real heat cycles over thousands of miles.

This is where things get interesting: while his film-strength and RPM tests are useful for comparing products side by side, they’re not a fair way to judge long-term oil additives. Because real engine protection isn’t just about extreme pressure—it’s about time, heat, and chemistry working together.

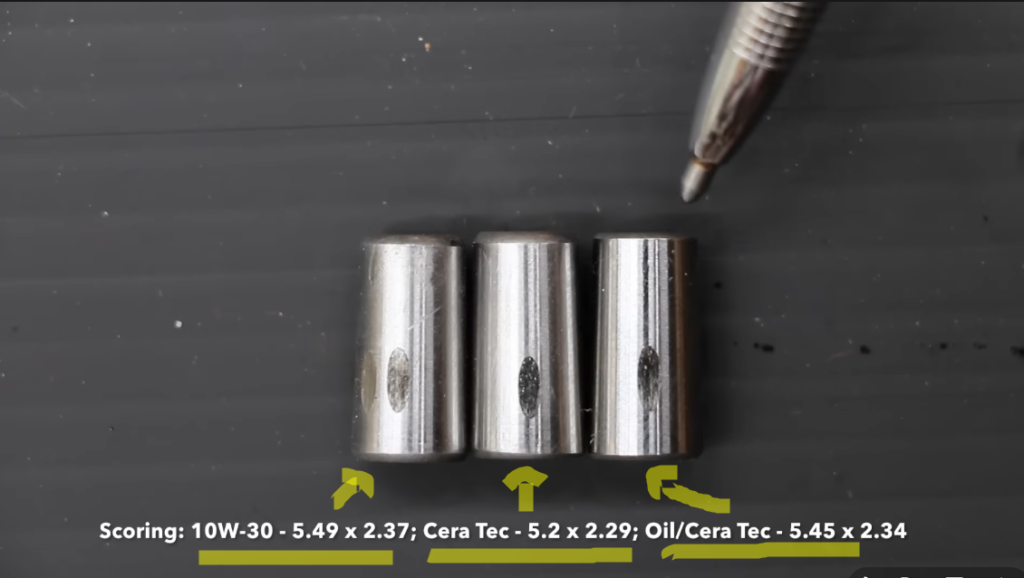

Project Farm – Lubricity / Film Strength Tests

Given those limits, let’s look at what Project Farm actually found. He mixed 6% CeraTec into 10W-30 oil and ran it through the same mechanical lubricity tester he used for MoS₂—same load, same 30 seconds.

Compared to plain oil, the CeraTec blend showed slightly better film strength. Not a huge jump—but noticeably better.

And here’s what stood out to me: compared to the last one we talked about, CeraTec actually outperformed MoS₂ in this test.

It’s not magic—but CeraTec did carry the load a bit better. That’s worth noting.

Internal Friction (RPM) Tests

Now, let’s talk about the test that really caught my attention. After the lubricity check, Project Farm ran the same small engine he used for MoS₂—but this time with CeraTec.

He recorded the RPM with plain 10W-30, then swapped in just over an ounce of CeraTec and ran it again under identical conditions.

Here’s what I noticed: the RPM went up noticeably. Since nothing else changed—same throttle, same load—that means internal friction dropped.

Compared to the last one we talked about (which showed no change), this is real, measurable proof. CeraTec isn’t just marketing—it actually reduces friction in a way you can see with basic tools.

Fuel Efficiency Test

Following the RPM test, Project Farm checked fuel efficiency the same way he did with MoS₂: a generator under a steady 1500-watt load, running until the tank was empty—first with plain oil, then with CeraTec added.

This time, the engine ran slightly longer with CeraTec—about a 1% gain in fuel efficiency.

On paper it sounds small, but here’s what I noticed: nobody gets rich off 1%. But over years of driving, that adds up. More importantly, it confirms that the friction reduction we saw in the RPM test actually translates to real-world savings—even if it’s modest.

Compression Test (What It Can’t Fix)

Now, after seeing those positive results, you might wonder—can CeraTec actually fix a worn-out engine? Project Farm tested that too.

He ran five full tanks of fuel with CeraTec in the oil, then measured cylinder compression.

The result? No improvement at all.

This is where things get important: CeraTec reduces friction and wear, but it doesn’t rebuild metal or restore lost compression.

Here’s what I keep coming back to: oil additives are about protection, not repair. And that’s a line we shouldn’t blur.

Summary From The Tests Data

So after looking at all of Project Farm’s data, here’s my take: CeraTec isn’t snake oil.

It actually delivered—reduced internal friction, a small but real fuel economy bump, and better film strength than plain oil.

But it also has limits: no compression gain, no fixing worn parts. It’s not a miracle cure.

Compared to the last one we talked about, CeraTec clearly performed better across the board.

That said, the improvements are modest and realistic—not dramatic. And honestly? That’s what I’d expect from a good additive: quiet help, not magic.

Real-World Criticism of Bench Tests

Now, even though Project Farm’s results are clear, a lot of users point out something important: CeraTec isn’t meant to work instantly.

They say it needs time—anywhere from 200 to 2,000 kilometers—to form its ceramic coating on metal surfaces. It works on the engine parts themselves, not just in the oil.

And that’s where bench tests hit a limit. They show what happens right away, but real coating chemistry needs heat cycles, load, and miles to fully develop.

Here’s what I noticed: if you judge CeraTec only on a one-hour test, you might miss how it behaves after a few hundred miles—which is exactly when it’s supposed to start working.

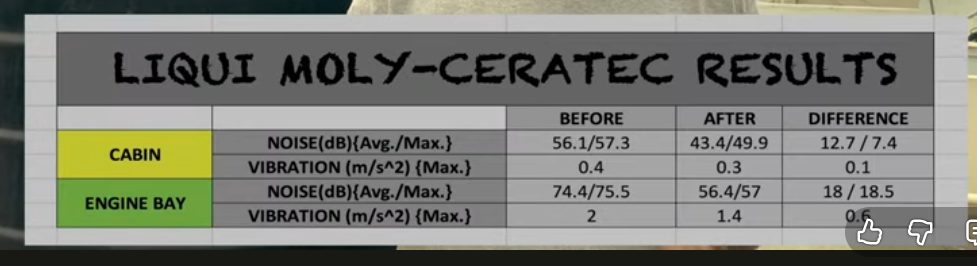

Real User Test – Ford EcoSport Diesel

That got me thinking—what happens in a real car? One user tested CeraTec in his Ford EcoSport Diesel. He added it during an oil change, drove about 600 km, then measured noise and vibration.

Inside the cabin, noise dropped from 56.1 dB to 43.4 dB—that’s a 12.7 dB reduction, which feels like a much quieter ride. Vibration went from 0.4 to 0.3 m/s²—a smaller but noticeable change.

But the biggest drop was under the hood: engine bay noise fell from 74.4 dB to 56.4 dB.

Here’s what I noticed: compared to the last one we talked about, CeraTec seems to really shine when it comes to quietness. In real driving, that smooth, hushed feel might be its strongest effect.

Knocking Reduction – Real Test

That quietness effect shows up in another way too—knock reduction. One user added CeraTec to his Tata Tiago, a small 3-cylinder car. He didn’t see big gains in mileage or vibration (which he expected), but something else changed.

Before, the engine would knock badly when shifting from low gears to high at low RPM. After CeraTec? The knocking disappeared—even under the same driving conditions.

I’ve seen this pattern before: across forums and comments, people keep saying CeraTec doesn’t always boost power or fuel economy, but it smooths out harshness and stops knock.

Here’s what I think: even if other benefits are subtle, fixing that kind of mechanical noise—and protecting against wear from it—might be worth it on its own.

Long-Term User Impressions

All this lines up with what long-term users say. Most report their engine feels quieter and smoother, but not right away—usually after around 300 miles of driving.

They also mention that CeraTec bonds to metal surfaces, so it doesn’t just wash out when you change your oil. That’s why Liqui Moly says it lasts up to 30,000 miles—the coating stays put.

Compared to the last one we talked about, CeraTec isn’t about raw protection during cold starts. Here’s what I’ve noticed: it’s more about refinement—less noise, less harshness, a calmer engine. Not a horsepower boost, but a smoother daily drive.

CeraTec vs MoS2 – When to Use Which

So which one should you actually use? It depends on your engine.

For cold starts and older engines—especially pre-2000 models—MoS₂ still has the edge. It sticks around when oil drains away, giving that critical startup protection.

But for modern, high-revving, turbocharged engines (think 2002 and newer), CeraTec is better suited. It handles heat and constant stress more effectively, and users report real smoothness gains.

Here’s what I’ve come to believe: they’re not competitors—they’re different tools for different generations of engines. MoS₂ is your rugged backup; CeraTec is your precision coating. Use the right one for your ride.

How the 30,000-Mile Coating Actually Works

Now, about that “30,000-mile” claim—it’s caused some confusion. So let me clear it up.

CeraTec’s ceramic particles fill in tiny scratches on metal surfaces and bond after about 500 miles of driving. Once that coating is set, it stays put—even when you drain and replace your oil.

You still change your oil on schedule. The additive isn’t meant to extend oil life; it’s meant to leave behind a durable layer that lasts through multiple oil changes.

Here’s what I realized: the “30,000 miles” refers to how long that coating stays effective, not how long you can skip an oil change. It’s a surface treatment, not an oil extender.

CeraTec vs MoS2: Alternating Strategy – Using Both Smartly

This got me thinking—what if you didn’t have to choose just one? Some users follow a simple cycle:

Start with an oil flush, then add CeraTec. At your next two or three oil changes, flush again and use MoS₂ instead. Then go back to CeraTec, and repeat.

Important: don’t mix them at the same time—too many additives can interfere with each other.

Here’s what I like about this approach: it balances ceramic smoothness with molybdenum’s startup protection, and it actually saves money over time. You’re not stuck betting on one tech—you’re using both, smartly, where they work best.

Conclusion: Final Positioning Before Next Product

So where does that leave us?

CeraTec clearly outperforms MoS₂ in modern engines—quieter operation, less knock, measurable friction reduction. It’s not magic, but it’s useful, especially when used right.

And remember: bench tests have limits, but they still help us compare fairly. What matters most isn’t brand loyalty—it’s using the right tool for your engine’s needs.

Smart use beats blind loyalty every time.

Now let’s move to the next product—and see how it stacks up against these two.

Motorkote Heavy Duty Hyper Lubricant

So far, we’ve looked at MoS₂ for cold starts and CeraTec for modern engines. Now we’re moving into something much stronger—and more controversial: MotorKote Hyper Lubricant.

The company says it’s not an oil additive. Instead, they call it a “hyper lubricant” that uses oil only as a delivery system to stick to metal parts—where it bonds and stays put.

Technically, that’s different from additives that mix into and change the oil itself.

But here’s what I think: even if they give it a fancy name, you still pour it into your oil, so for most of us, it functions like an additive. And that means we should judge it like one—by what it actually does, not what it’s called.

What MotorKote Used To Claims

Building on that, here’s what MotorKote actually says it does: it molecularly bonds to metal surfaces, reducing friction and heat—not by changing the oil, but by coating the engine parts themselves.

It claims this layer won’t wash away, even with oil changes or—get this—water exposure. And it’s supposed to last up to 80,000 kilometers, long after your oil is gone.

Most additives work in the oil, so they drain out when you change it. But MotorKote says the protection stays behind.

That’s a bold claim. And honestly, if it’s true, it would be different from almost everything else out there.

Testing MotorKote and Results

Given those bold claims, We wanted to test two things:

Does MotorKote actually reduce friction?

And more importantly—does it really stick to metal even when oil (or water) is present?

Because here’s the thing: most lubricants stop working the moment you drain the oil. But MotorKote says it keeps protecting—even in extreme conditions.

So he set out to see if that “bonded coating” idea holds up… or if it’s just marketing talk.

Lubricity (Film Strength) Test

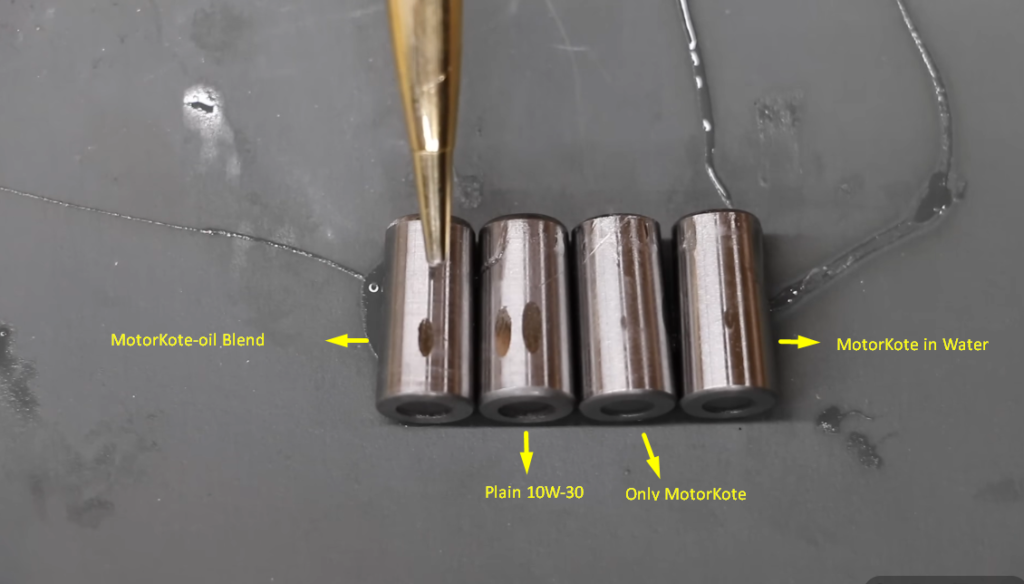

Following up on that, Project Farm ran the same lubricity test he used for MoS₂ and CeraTec—spinning a bearing under load for 30 seconds, comparing plain 10W-30, pure MotorKote, and a proper MotorKote-oil blend.

The results stood out: pure MotorKote showed almost no scoring, and even the blended version beat plain oil by a wide margin.

This wasn’t a tiny improvement—it was clear, visual proof of strong surface protection.

Here’s what I noticed: among all the additives he’s tested, MotorKote is one of the best in load-bearing tests. It’s not just hype—it actually holds up under pressure.

Water Resistance Test (The Crazy Part)

Now, this is where things get wild. After the lubricity test, Project Farm did something most people wouldn’t even try: he drained all the oil from a pre-treated lawnmower engine and filled the crankcase with nothing but water.

Then he ran it—for a full hour.

And somehow, the engine didn’t seize. When he checked it afterward, there was almost no metal debris, compression was strong, and the cylinder walls still had a faint coating.

This small-scale bearing test showed the same thing: even with water, protection held up.

Here’s what I think: almost nothing survives running without oil. But MotorKote did. And Project Farm didn’t just simulate—it was a real engine, under real heat and stress. That’s rare.

Real-World Driving Feedback

After seeing those extreme tests, I wondered: what do real drivers notice? Turns out, many say the engine feels smoother right away—better throttle response, less vibration, and even less blow-by. Some report a 1–2% bump in MPG, which makes sense: less friction means less heat, and less wasted energy.

But here’s what I keep coming back to: the fuel savings aren’t the big win. The real value is long-term wear reduction and lower operating temperatures. That’s what actually helps an engine last—not chasing a few extra miles per gallon.

Where People Misuse MotorKote

Now, even though MotorKote works well in engines, I’ve seen a lot of people make a risky move: they add it to their automatic transmission fluid.

Here’s the problem: transmissions don’t just need lubrication—they need controlled friction for clutches and bands to grip properly. Reduce that friction too much, and things start to slip.

And honestly, most transmission failures aren’t from gear wear—they’re from worn or slipping clutches.

So here’s my take: I would not use MotorKote in an automatic transmission. Just because something makes metal slippery doesn’t mean it belongs everywhere. In this case, a little friction is actually a good thing.

The Controversy: Chlorine & Sludge

All this impressive performance comes with a serious red flag—and it’s not just internet rumors. Some users and independent oil labs have reported that MotorKote may contain chlorinated compounds, like chlorinated paraffins.

Why does that matter? Because inside your engine, heat and moisture are always present. When chlorine meets water under high heat, it can form hydrochloric acid (HCl)—a corrosive chemical that attacks copper-lead bearings, rusts steel parts, and breaks down oil into sludge.

MotorKote says their product contains no “harmful substrate chemicals” and won’t damage engines. But here’s the problem: they don’t publish a full ingredient list, and there’s no public Safety Data Sheet (SDS) with actual chemical identifiers like CAS numbers. So we’re left guessing.

Now, about that AMS Oil bulletin: they did warn about an oil additive containing 27.2% chlorine linked to a failed Cummins diesel engine—the acid had eaten through lifters and valve guides, and the warranty was voided.

However, AMS Oil never publicly named the brand in their official bulletin or supporting documents. While some online forums and commenters have speculated that the product was MotorKote—based on its reputation and lack of ingredient transparency—there’s no confirmed proof it was actually MotorKote.

Here’s what I keep coming back to: yes, MotorKote looks amazing in tests—it reduces friction, survives water, smooths out engines. But chemistry matters more than slipperiness. Something can be incredibly slick and still cause slow, invisible damage. And without clear, verified ingredients? That’s a risk I wouldn’t take in my own engine.

Performance vs Safety Balance

So where does that leave us? MotorKote clearly delivers on performance: extreme friction reduction, real surface bonding, and even surviving full oil-loss scenarios. That’s impressive—maybe the best I’ve seen in bench and real-engine tests.

But on the other side, there’s real uncertainty: no clear ingredient list, possible sludge risks, and the chance of voiding your warranty if chlorine is present.

I’ll be honest—I love what it does. But I don’t like pouring something with uncertain chemistry into an expensive engine. Just because it makes things slippery doesn’t mean it’s safe long-term. And when I can’t verify what’s inside, I’d rather play it safe.

Better Modern Alternatives

Given those risks, it’s worth asking: are there safer options that still work well?

Yes—modern additives use boron compounds, molybdenum disulfide (MoS₂), and organic friction modifiers that reduce wear without the mystery chemistry.

Take CeraTec, for example: it combines boron and moly, delivers real smoothness and protection, and—importantly—has no chlorine controversy or hidden ingredients.

Here’s my take: MotorKote is powerful, no doubt. But for everyday driving in a modern engine, CeraTec gives you most of the benefit with far less risk. It’s not the flashiest, but it’s balanced, transparent, and safe for long-term use. And that matters more than extreme lab results.

Who Should and Shouldn’t Use MotorKote

So who should actually use MotorKote—and who should skip it?

It might make sense for older, out-of-warranty engines that are already worn or pushed hard—like work trucks, farm equipment, or daily beaters. In those cases, the extreme protection could help stretch engine life.

But it’s not ideal for new engines under warranty, automatic transmissions (remember: clutches need friction), or modern engines with lots of aluminum parts, where acid corrosion could be a real risk.

Here’s how I see it: if your engine is cheap, tough, and already abused, MotorKote might give it a fighting chance. But if you’re driving something expensive and modern, chemistry safety matters more than maximum slipperiness. In that case, I’d go with something cleaner and clearer—like CeraTec.

Lucas Oil Heavy Duty Oil Stabilizer

So far, we’ve looked at MoS₂—a solid lubricant—and CeraTec—a ceramic coating. But Lucas Oil Stabilizer? It’s something else entirely.

It’s not a friction additive. Instead, it changes how the oil itself behaves—making it thicker, stickier, and more resistant to breaking down under heat and stress.

Here’s what I’ve noticed: Lucas isn’t selling miracles. It’s about giving tired, worn-out engines a little extra cushion—so they can keep running smoother, quieter, and longer. It’s old-school support, not high-tech magic.

What Lucas Oil Stabilizer Actually Is

Now that we’ve set it apart, let’s be clear: Lucas Heavy Duty Oil Stabilizer is 100% petroleum-based mineral oil—no synthetics, no mystery powders. It’s thick, sticky, and pours like light gear oil.

And importantly, it doesn’t contain chlorine, PTFE (Teflon), molybdenum disulfide, or solvents—so it avoids the chemical risks we saw with other products.

Its job isn’t to coat metal like CeraTec or MoS₂. Instead, it reinforces the oil film itself, acting as a viscosity modifier and seal conditioner—helping oil stay put longer in worn engines.

Here’s what I see: Lucas isn’t about chemistry tricks. It’s about making your existing oil work harder and last longer where it’s needed most.

Why People Use Lucas in Real Life

So why do so many people reach for Lucas? Because it helps when engines start showing their age.

If your engine is burning oil, has low oil pressure, or makes that annoying lifter tick, Lucas can quiet things down. It’s especially popular in older diesels, farm equipment, and high-mileage trucks with worn piston rings or valve guides.

The thick, sticky oil clings to parts longer—so even when clearances are loose, there’s still some film holding on.

But here’s the reality: it’s not a fix. It won’t rebuild worn metal. It just gives a tired engine a little more breathing room.

And that’s exactly where Lucas shines—not in perfect engines, but in ones that are already imperfect. It’s support, not surgery.

How Lucas Claims to Help Engines

Lucas makes a long list of promises: it boosts oil life, reduces oil burning and blow-by, raises oil pressure, quiets rough idles, and even claims to improve power and MPG.

But look closer—these aren’t about rebuilding worn parts. They’re all about how the oil behaves: staying thicker longer, sealing better around loose rings, and keeping pressure up in tired engines.

It’s aimed squarely at high-mileage cars, diesel trucks, race engines, and towing rigs—places where oil gets hot, thin, and stressed fast.

Here’s what I’ve learned: Lucas isn’t pretending to fix metal. It’s trying to make the oil do more with what’s already there. And in the right engine? That can actually help.

How It’s Used

Now, if you’re thinking about using Lucas, the mixing ratio really matters. The standard dose is about 20% of your total oil capacity—so for a 5-quart system, that’s 1 quart of stabilizer.

It blends with both conventional and synthetic oils, so it’s flexible. People commonly use it in classic cars, diesel pickups, tractors, and work trucks—places where engines run hot and hard.

But here’s what I’ve seen: because Lucas is so thick, using too much can actually hurt oil flow, especially in cold weather or tight-tolerance engines. The treat rate isn’t just a suggestion—it’s key to making it work without causing new problems. Less isn’t better, but more definitely isn’t either.

The Science Logic Behind Lucas

So why does Lucas even make sense?

It comes down to what happens to oil over time.

Under heat and heavy load, regular oil thins out—a process called shear thinning—and loses its ability to hold a strong film between moving parts. That’s when metal starts touching metal.

Lucas fights that by boosting viscosity stability, helping the oil stay thick enough to keep a protective layer, even when things get hot.

From a thermodynamics standpoint, a thicker, more stable oil resists thermal breakdown better than thin oil alone.

Here’s what I’ve realized: Lucas isn’t about chemical friction fighters like moly or ceramic. It’s simpler—it just keeps the oil from disappearing under stress. No magic, just physics.

The Big Criticism (Modern Engines Warning)

All this sounds great—until you put Lucas in the wrong engine.

Modern engines, especially turbocharged ones, are designed for very specific oil viscosities, like 0W-20 or 5W-20. They rely on thin oil to flow quickly through tight spaces and feed turbos and bearings fast.

But Lucas is thick. In cold weather, that thickness gets worse—oil moves slower, and during startup, parts might run dry for a few extra seconds. That’s called a dry start, and it causes real wear.

Here’s what I’ve learned: Lucas Heavy Duty isn’t a one-size-fits-all fix. It’s situational—great for old, loose engines, but risky in modern, precision-built ones. Know your engine before you pour.

Project Farm Head-to-Head Test (Lucas vs STP)

After all these claims, Project Farm put Lucas to the test—head-to-head with STP—to see if either really delivers.

First, in the film strength test, both additives showed only minor differences. Pure Lucas scored slightly better than pure STP, but when mixed as directed, the results were nearly identical. And honestly, Lucas’s thick texture made it harder to get clean, consistent readings—not clearer ones.

Then came the endurance test: two identical engines, one with Lucas, one with STP. After hours of running, the Lucas engine ran 10–15°F hotter. Why? Thick oil doesn’t always cool better—it can actually trap heat instead of carrying it away.

Finally, the ultimate stress test: drain all the oil and run them dry. Both engines seized within minutes—connecting rods shattered, pistons melted, total destruction. Lucas didn’t save its engine.

Here’s what that tells me: no matter how thick or sticky your stabilizer is, it can’t replace oil itself. Under true oil starvation, Lucas offers no magic shield. It helps in normal wear scenarios—but it’s not a safety net for oil loss.

What The Test Really Proves (And What It Doesn’t)

So what does Project Farm’s test actually tell us?

It proves Lucas isn’t a miracle shield—especially when oil is completely gone. But it doesn’t prove Lucas is useless in real life.

Why? Because those tests push engines into extreme, unrealistic abuse: running with no oil at all. Most of us never face that.

In daily driving, Lucas isn’t trying to survive oil starvation. It’s about slowing wear in engines that already burn oil or have low pressure.

Here’s my take: the test shows Lucas won’t save you from mechanical failure—but it might help a worn engine run smoother and last a little longer under normal conditions. That’s a different job entirely.

Cold Climate

All this brings us to cold climates—like Minnesota in January. Thick oil, like Lucas Heavy Duty, gets even thicker when it’s freezing. That means slower flow, delayed lubrication, and a higher risk of dry starts—where metal parts grind before oil arrives.

In cold weather, you need oil that moves fast, not one that clings hard. Thin oils flow quicker, coat parts sooner, and reduce startup wear.

So here’s the thing: Lucas Heavy Duty is the worst choice for cold climates. It’s built for heat and heavy loads—not winter mornings.

If you’re in a cold area and still want a Lucas product, go with Lucas Pure Synthetic Stabilizer or their Low Viscosity Stabilizer—both are thinner and flow better when it’s cold. For high-mileage engines, the High Mileage version is a middle ground.

But remember: Heavy Duty is for hot, hard-working engines, not freezing garages. In the cold, flow matters more than thickness.

Where Lucas Heavy Duty Actually Belongs

So where does Lucas Heavy Duty actually belong?

It shines in older, worn-out engines—diesel trucks, tractors, industrial machines, or anything that’s burning oil, smoking, or losing compression. In those cases, its thickness helps fill gaps and keep pressure up.

But it’s a poor fit for new cars, especially modern turbo direct-injection engines that need thin, fast-flowing oil. Using it there can hurt more than help.

Here’s how I see it: Lucas Heavy Duty isn’t a performance upgrade. It’s a support tool—like a brace for an aging engine. It won’t make your car faster or newer, but it might help a tired motor last a few more miles without falling apart. And that’s valuable—if you’re using it in the right place.

Lucas vs CeraTec

So how do I choose between Lucas and CeraTec? It comes down to what your engine actually needs.

Lucas thickens oil—it’s great at masking symptoms like ticking lifters or oil burning in old, worn engines. But it doesn’t reduce friction chemically; it just props things up.

CeraTec, on the other hand, uses ceramic and moly chemistry to reduce friction at the surface level, helping newer engines stay cleaner and smoother over time.

My rule is simple:

- New or modern engines? Go with CeraTec.

- Old, high-mileage, or diesel workhorses? Lucas Heavy Duty makes more sense.

Because here’s the truth: different problems need different solutions. One isn’t better overall—they’re just right for different jobs.

Final Verdict

o where do I land on Lucas? It’s not snake oil—but it’s also not miracle oil.

It works best for one thing: helping tired, worn-out engines last a little longer. It quiets noise, slows oil burn, and keeps pressure up when clearances are loose.

But it won’t rebuild metal, fix compression, or turn an old engine new again.

Here’s my honest take: Lucas doesn’t make engines better—it makes bad engines last longer. And sometimes, that’s exactly what you need. Just don’t expect it to do more than that.